What is bismuth?

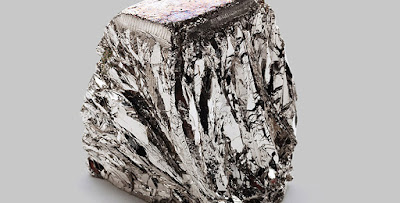

Bismuth is a gleaming and fragile metal that is much of the

time found in low-soften amalgams. Interest for bismuth metal has become in the

course of recent years in extensive part because of its compelling use as a

substitute for lead.

Properties:

Nuclear Symbol: Bi

Nuclear Number: 83

Component Category: Post-move metal

Thickness: 9.78 g/cm3 (20°C)

Liquefying Point: 272 °F (521 °C)

Breaking point: 1564 °F (2847 °C)

Moh's Hardness: 2.25

Attributes:

Bismuth is a fragile, shiny green metal that has a low

softening temperature and high particular gravity.

Being both stable and non-dangerous, bismuth is frequently

utilized as a substitution for harmful metals, for example, antimony, cadmium,

lead, and mercury.

Like water, bismuth is less thick as a strong than as a

fluid (it extends as it cools), a property one of a kind for a metal. Of all

the metal components, bismuth likewise has the most astounding electrical

resistance and the least thermo-conductivity (with the exception of mercury),

and in addition the most astounding Hall Effect (increment in electrical

resistance when set in an attractive field).

History:

Bismuth was first perceived amid the Middle Ages, in any

case, with no capacity to disengage the metal it was frequently mistaken for

tin, lead, antimony and zinc. In 1450, German minister Basil Valentine

initially made reference to wismut, or 'white lead', which would later be

Latinized as bisemutum.

Extraction of bismuth for use in shades started as ahead of

schedule as the fifteenth century from silver mines in Schönberg, Germany. In

the mid-eighteenth century, look into by Johan Heinrich Pott and Claude

Geoffroy prompted a superior comprehension of bismuth and its exceptional

properties.

Restorative professionals were, right now, likewise getting

to be plainly mindful of bismuth's helpful properties in treating gastric

conditions.

The main metallurgical uses for bismuth were in pewter

combinations, where it was utilized with lead and tin to bring down the

dissolve temperatures, and in amalgams with antimony for printing press sort

metals.

A noteworthy jolt to the bismuth business came in the

mid-1990s with the Safe Drinking Water Act Amendment (1995), which denied the

nearness of lead in drinking water installations in the US. For as far back as

20 years, the sans lead development has brought about bismuth's selection in an

extensive variety of utilizations.

Creation:

Bismuth frequently happens actually in the sulfide mineral

bismuthinite (Bi2S3) or the oxide metal bismite (Bi2O3). Be that as it may,

extraction of such minerals exclusively for its bismuth substance is

infrequently temperate and bismuth is, rather, principally created as a

by-result of lead refining. In China, vast amounts of bismuth are likewise

separated from tungsten, tin and zinc metals.

Extraction of bismuth metal from lead regularly happens by

means of one of two procedures; the Betterton-Kroll Process or the Betts

Process.

The Betterton-Kroll Process isolates bismuth from lead

through the presentation of calcium or magnesium into a liquid arrangement of

the lead and bismuth. The subsequent calcium or magnesium bismuthide, being

lighter than liquid lead ascends to the surface as dross (strong pollutions)

and can then be evacuated. The dross is then treated with chlorine at

temperatures of around 572-932°F (380-500°C) to evacuate the magnesium or

calcium.

High virtue bismuth is created after treatment utilizing

sodium hydroxide.

The Betts Process includes electrolytic refining of lead

bullion. In a synergist arrangement, unadulterated metallic lead plates onto

the anode, while polluting influences, including bismuth, settle to the base of

the vessel. The sloppy blend of metals can be liquefied to deliver a metal

composite and a bismuth-rich slag, which is then decreased with carbon to create

bismuth metal.

In China, blended concentrates of bismuth are delivered by

draining, attractive partition as well as differential buoyancy methods.

Concentrates are then purified to create unrefined bismuth for refining.

The biggest bismuth creating nations are China, Peru, Mexico

(unrefined and refined) and Belgium (refined). In 2013, the US Geological

Survey assessed worldwide world refined bismuth creation to be around 17,000

metric tons.

Of this, Chinese creation represented roughly 90 percent.

With more than 70 bismuth mines, China likewise represents most by far of

worldwide bismuth saves.

Real bismuth makers incorporate Hunan Nonferrous Group

(China), Shizhuyuan Nonferrous (China), Penoles (Mexico), Sidech (Belgium), and

MCP (UK).

Applications:

Because of bismuth's weakness, unadulterated types of the

metal are not utilized as a part of metallurgical applications. It is, in any

case, utilized as an added substance amalgam in copper, aluminum, iron and

steel as a substitute for lead and to toughen and make composites that are more

machineable.

Take after the connection here to peruse more about bismuth

metal applications.

Sources:

Elementymology and Elements Multidict. Bismuth.

http://elements.vanderkrogt.net/element.php?sym=Bi

US Geological Survey. Bismuth.

http://minerals.usgs.gov/minerals/bars/product/bismuth/

Emoticon